- Home page

- 3D Printers and accessoires

- Modeling

- Molding & Casting

- Tin Silicones

- Platinum Silicones

- Dragon Skin™ Series

- Ecoflex™ Series

- Equinox™ Series

- Mold Star™ Series

- Rebound ™ Series

- Smooth-Sil™ Series

- SORTA-Clear™ Series

- Body Double™ Series

- Psycho Paint™

- Platsil Gel & Deadener

- Rubber Glass ™

- Encapso® K

- Solaris™

- Soma Foama™

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- PU-Rubbers

- Alginate

- PU-Resins

- PU Foam

- Epoxy Resins

- Polyester Resins

- Gypsum & Cement

- Latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica Latex Rubber

- Monstermakers Foam Latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Coating/Dipping Latex

- Holden's Body Latex™ - Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast

- Prince August

- Concrete Mixtures

- Jesmonite Acryl System

- Buddy Rhodes™ Concrete Products

- Seal and Release

- Additives

- Pigments

- Jesmonite liquid Pigments

- Pure Pigments powder

- Ultra Fine Pigments powder

- Silc Pig™ pigments for silicone

- Glow Worm™ Fluorescent Pigments

- Cryptolyte™ Glow in the Dark

- Silicone Pigments - SilcPig™ Electric fluorescent

- Siltone Pigment for Silicone

- SilTone Kits

- Silicone Coloring System - FuseFX

- Silicone Coloring System S.A.M

- Key Pigments for silicone

- Kryolan Flock Fiber

- Latex Pigments

- Polyester Pigment

- UVO™- PU-pigments - UV-Resistant

- SO-Strong - PU-pigments

- Ignite™ fluorescent PU-pigments

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Powders

- Paints

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Vallejo Acrylic Paints

- Vallejo Metal Color

- Maker Pro Paint Additive

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- MM Latex Paint

- MM Latex Paint Base

- FFX LY-series paints

- FFX F-series paint

- FFX M-series paints

- jesmonite paint

- Fillers and Finishing

- Solvents & Thinners

- Adhesives

- Tools

- Equipment

- Special Make-Up

- Cannom Grease Paint

- Skin Illustrator Palettes

- Skin Illustrator Liquid

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60 ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras Liquids 60ml

- Mardi Gras Liquids 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Alphabetical all

- Skin Illustrator Concentrates

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Palettes

- PAX Paints Thomas Suprenant

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Old Age Stipple

- Holden's Cosmetic Latex™

- Tattoo Sheets

- Brushes Make-Up

- Stamps & Molds

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special effects

- Prostetic Materials

- Help me choose

- Literature

- FormX Academy

Epoxacast

Buy Smooth-On at FormX

Smooth-On is one of the worlds leading manufaturers 3D modeling materials such as mold-making, casting and special effects materials but also industrial casting resins, adhesives and equipment. FormX is main distributor of Smooth-On products in Europe.

Epoxy Casting Resins

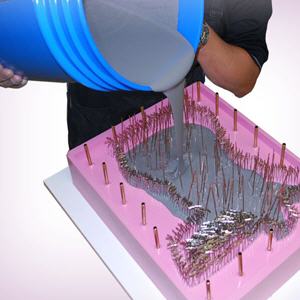

Epoxy casting resins for casting and encapsulation.

The EpoxAcast series are general purpose casting epoxy resins that are low cost and versatile. They features a low mixed viscosity for minimal bubble entrapment. Choose Fast, Medium or Slow catalyst to fit your project. You can also use HT Hardener to give your castings higher heat resistance.

Technical bulletin Epoxacast 650

Technical bulletin Epoxacast 655

Technical bulletin Epoxacast 670

Technical bulletin Epoxacast 690

Epoxacast 650

EpoxAcast® 650 is a mineral filled general purpose casting epoxy resin that is low cost and versatile. It features a low mixed viscosity for minimal bubble entrapment. Choose Fast, Medium or Slow catalyst to fit your project. You can also use HT Hardener to give your castings higher heat resistance.

EpoxAcast® 650 is used for making hard dies for metal stamping as well as patterns and fixtures. It is also used for electrical encapsulation to extend the life cycles and enhance the performance of potted electronic devices. The high compressive strength of EpoxAcast® 650 makes it ideal for making stamping dies for production pressing of metal ornaments.

EpoxAcast 650 Base (Part A) & Hardener (Part B) sold separately. Choose from 101 FAST, 102 MEDIUM, 103 SLOW or HT Hardener

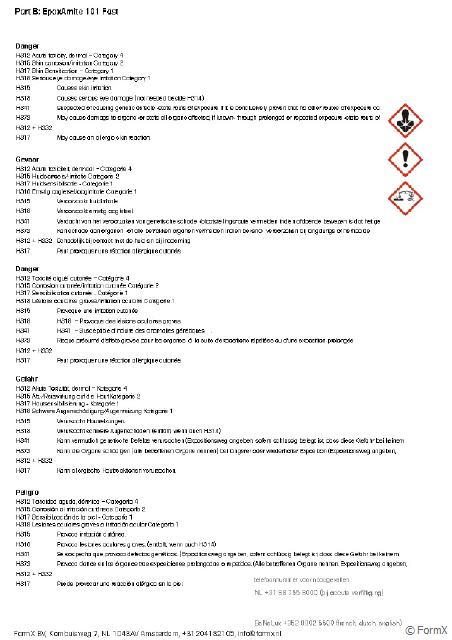

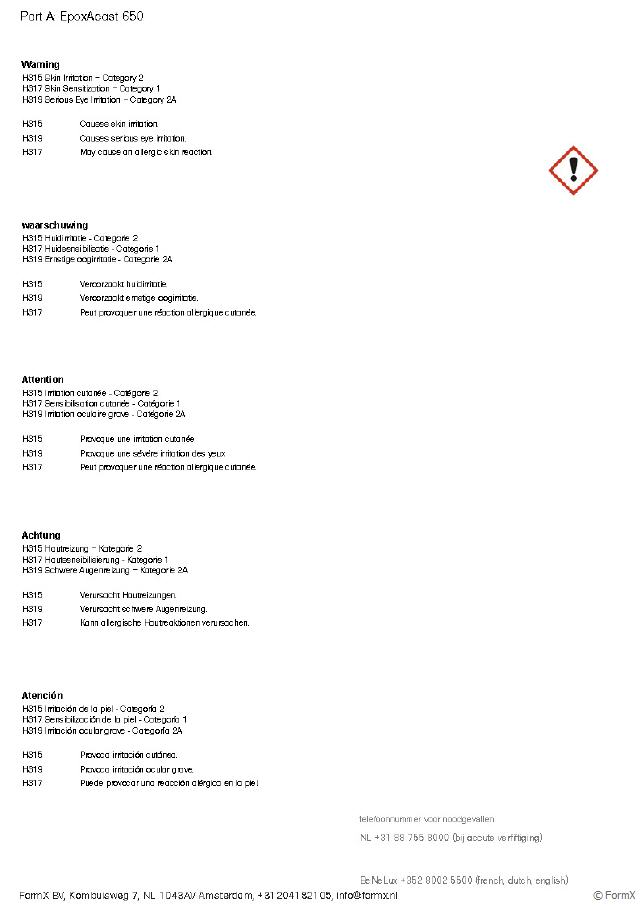

Epoxacast 650 Safety

- Read the safety information label. Click on the image

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

epoxacast 650

Epoxacast 650 hardener sold seperately

| Epoxacast 650 | mixing ratio | pot life | cure time |

|---|---|---|---|

| 101 fast hardener | 100A:12B | 20 minutes | 1 hour |

| 102 medium hardener | 100A : 13B | 90 minutes | 4 hours |

| 103 slow hardener | 100A : 14B | 3,5 hours | 24 hours |

| HT high temperature hardener | 100A : 10B | 3,0 hours | 24 Hours followed by: Heat cure for 2 hrs at 175°F/80°C followed by 3 hrs at 300°F/150°C |

Hardener Safety Information

Epoxacast Hardeners

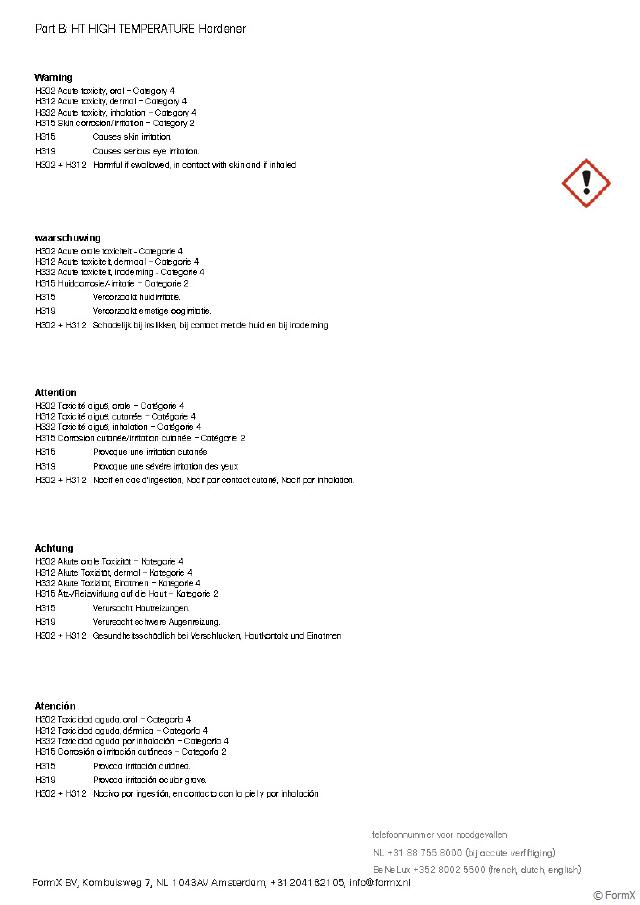

Epoxacast HT Hardener Safety Information

- Read the safety information label. Click on the image

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

Epoxacast HT Hardener

Epoxacast 655

EpoxAcast® 655 (formerly Metalset® A-30) is a versatile aluminum filled castable epoxy resin that is very hard and strong. It is dimensionally stable, even when mass cast up to 512 in3/ 8,390 cm3. Different hardener speed options are available depending on your project requirements. Maximum heat resistance is achieved using HT HIGH TEMP hardener (up to 225°F/108°C).

Cured EpoxAcast® 655 epoxy has high physical properties and is used for a variety of applications including making hard tooling, vacuum forming dies/molds, injection molds, foundry patterns, jigs and fixtures and metal forming dies. Depending on project requirements, Part A Base can be mixed with 101 FAST, 102 MEDIUM, 103 SLOW or HT HIGH TEMP hardeners.

EpoxAcast 655 Base (Part A) & Hardener (Part B) sold separately. Choose from 101 FAST, 102 MEDIUM, 103 SLOW or HT Hardener

655 safety

- Read the safety information label. Click on the image

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

epoxacast 655

Epoxacast 655 hardener sold seperately

| Epoxacast 655 | mixing ratio | pot life | cure time |

|---|---|---|---|

| 101 fast hardener | 100A:10B | 30 minutes | 90 minutes |

| 102 medium hardener | 100A : 11B | 75 minutes | 135 minutes |

| 103 slow hardener | 100A : 12B | 3 hours | 195 minutes |

| HT high temperature hardener | 100A : 8B | 4 hours | 24 Hours followed by: Heat cure for 2 hrs at 175°F/80°C followed by 3 hrs at 300°F/150°C |

Hardener Safety Information

Epoxacast Hardeners

Epoxacast HT Hardener Safety Information

- Read the safety information label. Click on the image

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

Epoxacast HT Hardener

Epoxacast 670HT

EpoxAcast® 670 HT (formerly 20-136) is an epoxy casting compound which offers high heat resistance up to 350° F/177° C if post cure schedule is used. EpoxAcast® 670 HT features a relatively low viscosity that ensures minimal bubble entrapment. EpoxAcast® 670 HT also offers an extra long working time of 3 hours.

Castings cure with negligible shrinkage and are very hard, very strong and heat resistant. EpoxAcast® 670 HT is ideal for making vacuum form molds, foundry patterns, forming dies & fixtures, hard rollers, industrial parts and high impact tools. EpoxAcast® 670 HT is also suitable for encapsulation applications or for use as a high temperature epoxy adhesive for bonding a variety of surfaces.

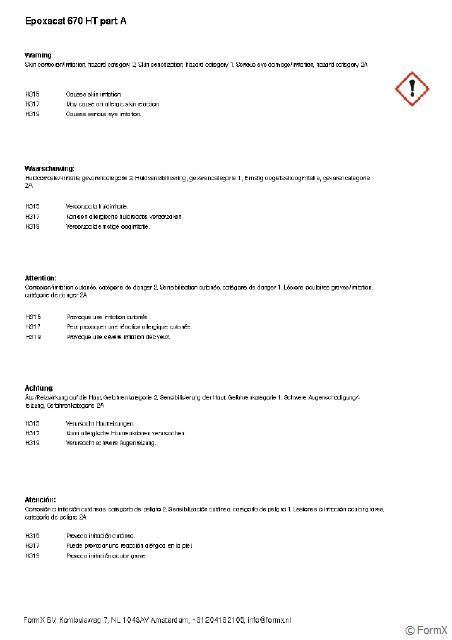

670 HT Safety Information

epoxacast 670

EpoxAcast 670 HT Hardener

| Epoxacast 670 | mix ratio | pot life | cure time |

|---|---|---|---|

| Epoxacast 670 HT hardener | 100A : 16B by weight | 3 hours | 24 Hours followed by: Heat cure for 2 hrs at 175°F/80°C followed by 3 hrs at 300°F/150°C |

Epoxacast HT Hardener Safety Information

- Read the safety information label. Click on the image

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

Epoxacast HT Hardener

Epoxacast 690 Clear

EpoxAcast® 690 is a UV resistant clear casting epoxy resin that is ideal for making clear jewelry/beads or replacement lenses for kit cars and other applications requiring a rigid, clear finished product. EpoxAcast® 690 can be colored with SO-Strong® color tints.

EpoxAcast® 690 is also suitable for making clear molds and prototype parts. Castings cure with negligible shrinkage and are very hard and strong. EpoxAcast® 690 is also suitable for encapsulation applications for electronic assemblies where component identification is necessary. Recommended casting thickness maximum; 2 in. / 5 cm.

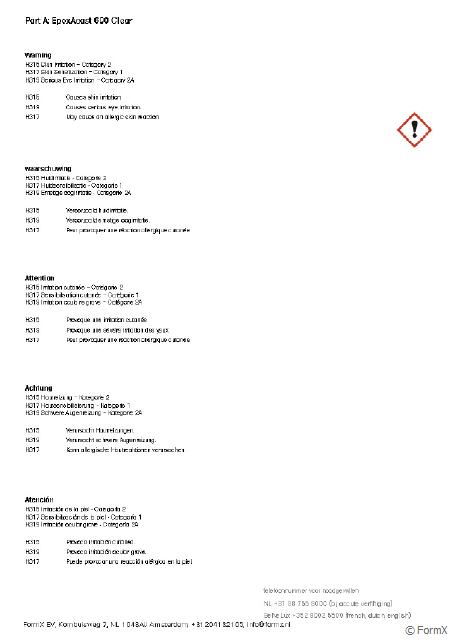

Safety Information

epoxacast 690

EpoxAcast 690 Clear Hardener

| Epoxacast 690 | mix ratio | pot life | cure time |

|---|---|---|---|

| Epoxacast 690 clear hardener | 100A : 30B by weight | 5 hours | 24 hours |

Epoxacast HT Hardener Safety Information

- Read the safety information label. Click on the image

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

HT Hardener

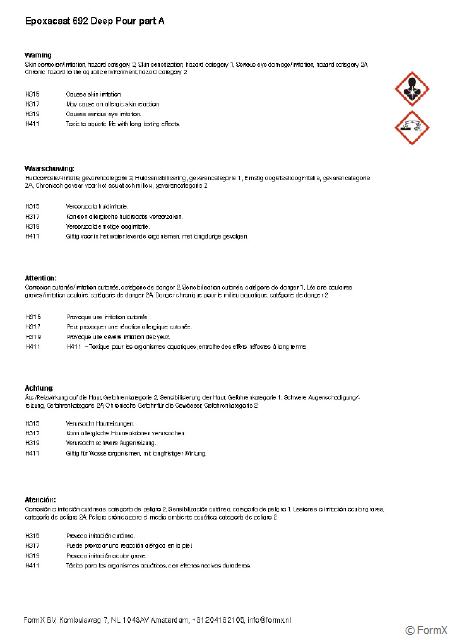

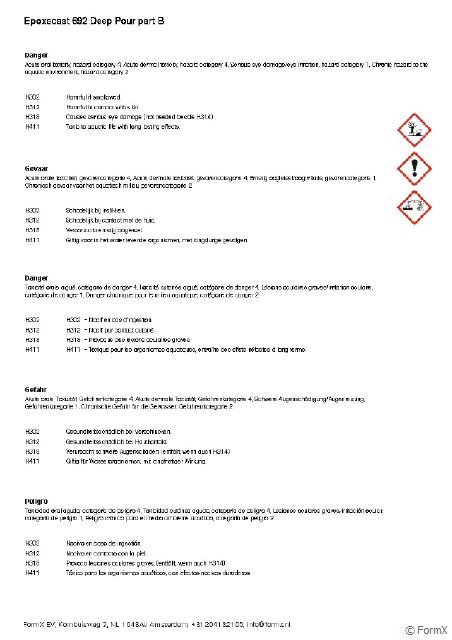

692 Safety Informations

EpoxAcast 692

Hardener Safety Information

Epoxacast Hardeners

HT Hardener safety

-Read the safety information label. Click on the image

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

HT Hardener

Epic

Preparation– Avoid breathing fumes - use in a well ventilated area at minimum. NIOSH approved respirator is recommended. Wear safety glasses, long sleeves and rubber gloves to minimize skin contact.

Materials should be stored and used in a room temperature environment (73°F/23°C). Elevated temperatures will reduce pot life. EpoxAcast® 670 Resin and Hardener must be properly measured and thoroughly mixed to achieve full, high-strength, solid-cure properties.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Applying A Release Agent – For releasing epoxy from non-porous surfaces such as resin, metal, glass etc., use Ease Release 200 or 205 (available from Smooth-On) to prevent adhesion.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the mold or model. Follow with a light mist coating and let the release agent dry for 30 minutes.

Pre-mix Part A Thoroughly - Separation may have occurred in transit or storage. Pre-mix for 2 minutes prior to dispensing to a uniform consistency using a straight edge paddle (paint stirrer) or turbo mixer (drill attachment).

Measuring / Dispensing – Accurate measurement by weight is required for the material to cure properly and develop full physical properties. Dispense Parts A and B in proper proportions into clean plastic, metal or wax-free paper containers. You must use an accurate scale (gram scale or triple beam balance scale) to weigh these components properly. Do not attempt to measure components by volume.

Adding Color & Fillers - EpoxAcast® 670 HT can be colored with SOStrong® color tints (from Smooth-On). Pre-mix tint with Part A thoroughly and then add Part B. A variety of dry fillers can also be added. Pre-mix dry filler with Part A before adding Part B.

Mixing – Be sure mixing utensils are clean and free of any potential contaminants such as dirt, dust or grease. Mix Parts A and B thoroughly for at least 3 minutes with a square edged mixing stick. Be aggressive and scrape sides and bottom of mixing container several times. Use the square edge of mixing stick to bring material off of the sides of container and blend. If using a drill mixer, follow with hand mixing as directed above to ensure thorough mixing.

Vacuuming - EpoxAcast® 670 HT is low in viscosity compared to other epoxy cating systems and does not require vacuum degassing. If you choose to vacuum the material, subject mixture to 29 h.i.g. mercury in a vacuum chamber until mixture rises, breaks and falls. Allow for 5 times volume expansion in mixing container.

Pouring – If casting EpoxAcast® 670 into a rubber mold, pour mixture in a single spot at the lowest point of the mold. Let the mixture seek its own level. A uniform flow will help minimize entrapped air.

If making vacuum forming molds, it is best to use piano wire (15/1000 inch gauge) to make vacuum holes.

Cure Time: Refer to specified Cure Times in Handling Properties section. Cured material will be hard and unable to penetrate with a finger nail. Cured epoxy can now be dry sanded. If machining or sanding, wear NIOSH approved mask to prevent inhalation of particles. Pot life and cure time values are dependent on mass and mold configuration, as epoxies are mass-sensitive.

Heat Curing - For best results, EpoxAcast® should be heat cured in an dedicated oven. Cure at 175° F / 80° C for two hours, followed by three hours at 300° F / 150° C. Allow material to cool to room temperature before use.

Painting – Cured EpoxAcast® can be painted or primed and then painted with acrylic enamel paints. Let paint fully dry before putting part into service.

Removing Epoxy – Uncured / Non-curing epoxy: Scrape as much material as possible from the surface using a scraper. Clean the residue with E-POX-EE KLEENER®, lacquer thinner, acetone or alcohol. Follow safety warnings pertaining to solvents and provide adequate ventilation.

Guide

Let us help you find your way.

The list below may help you find what you are looking for via an alternative path.