- Home page

- 3D Printers and accessoires

- Modeling

- Molding & Casting

- Tin Silicones

- Platinum Silicones

- Dragon Skin™ Series

- Ecoflex™ Series

- Equinox™ Series

- Mold Star™ Series

- Rebound ™ Series

- Smooth-Sil™ Series

- SORTA-Clear™ Series

- Body Double™ Series

- Psycho Paint™

- Platsil Gel & Deadener

- Rubber Glass ™

- Encapso® K

- Solaris™

- Soma Foama™

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- PU-Rubbers

- Alginate

- PU-Resins

- PU Foam

- Epoxy Resins

- Polyester Resins

- Gypsum & Cement

- Latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica Latex Rubber

- Monstermakers Foam Latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Coating/Dipping Latex

- Holden's Body Latex™ - Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast

- Prince August

- Concrete Mixtures

- Jesmonite Acryl System

- Buddy Rhodes™ Concrete Products

- Seal and Release

- Additives

- Pigments

- Jesmonite liquid Pigments

- Pure Pigments powder

- Ultra Fine Pigments powder

- Silc Pig™ pigments for silicone

- Glow Worm™ Fluorescent Pigments

- Cryptolyte™ Glow in the Dark

- Silicone Pigments - SilcPig™ Electric fluorescent

- Siltone Pigment for Silicone

- SilTone Kits

- Silicone Coloring System - FuseFX

- Silicone Coloring System S.A.M

- Key Pigments for silicone

- Kryolan Flock Fiber

- Latex Pigments

- Polyester Pigment

- UVO™- PU-pigments - UV-Resistant

- SO-Strong - PU-pigments

- Ignite™ fluorescent PU-pigments

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Powders

- Paints

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Vallejo Acrylic Paints

- Vallejo Metal Color

- Maker Pro Paint Additive

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- MM Latex Paint

- MM Latex Paint Base

- FFX LY-series paints

- FFX F-series paint

- FFX M-series paints

- jesmonite paint

- Fillers and Finishing

- Solvents & Thinners

- Adhesives

- Tools

- Equipment

- Special Make-Up

- Cannom Grease Paint

- Skin Illustrator Palettes

- Skin Illustrator Liquid

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60 ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras Liquids 60ml

- Mardi Gras Liquids 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Concentrates

- Fleshtone liquid Concentrate 60ml

- Dark Fleshtone liquid Concentrate 60ml

- FX liquid Concentrate 60ml

- FX liquid Concentrate 120ml

- Alchemy liquid Concentrate 60ml

- Grunge liquid Concentrate 60ml

- Mardi Gras liquid Concentrate 60 ml

- Necromania liquid Concentrate 60ml

- Necromania liquid Concentrate 120ml

- Concentrate Alphabetical

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Palettes

- PAX Paints Thomas Suprenant

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Old Age Stipple

- Holden's Cosmetic Latex™

- Tattoo Sheets

- Brushes Make-Up

- Stamps & Molds

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special effects

- Prostetic Materials

- Help me choose

- Literature

- FormX Academy

XTC-3D

Buy Smooth-On at FormX

Smooth-On is one of the worlds leading manufaturers 3D modeling materials such as mold-making, casting and special effects materials but also industrial casting resins, adhesives and equipment. FormX is main distributor of Smooth-On products in Europe.

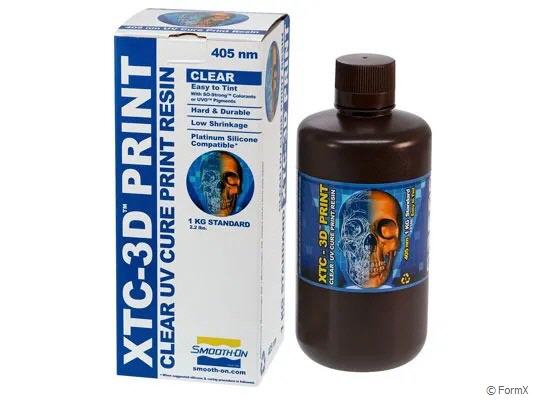

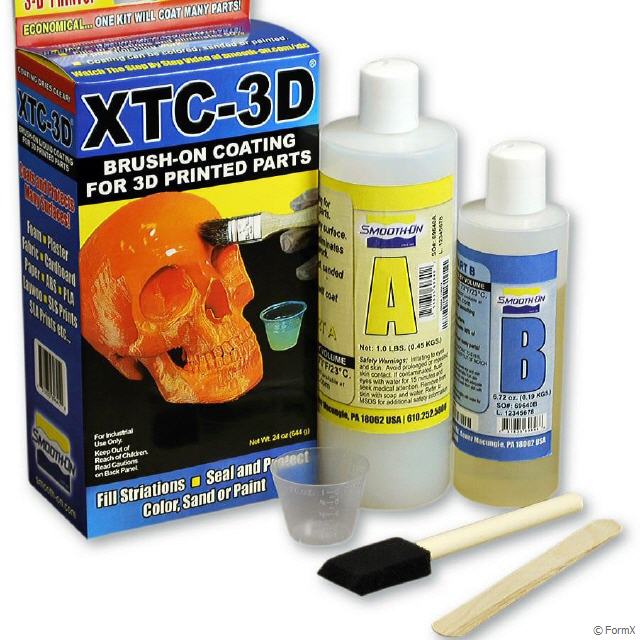

XTC-3D

Brush-On liquid coating for 3D printed parts Coats and protects many surfaces! Foam, Plaster Fabric, Cardboard Paer, ABS, PLA, Plywood, SLS Prints, SLA Prints etc.

Technical bulletin XTC-3D

XTC-3D products

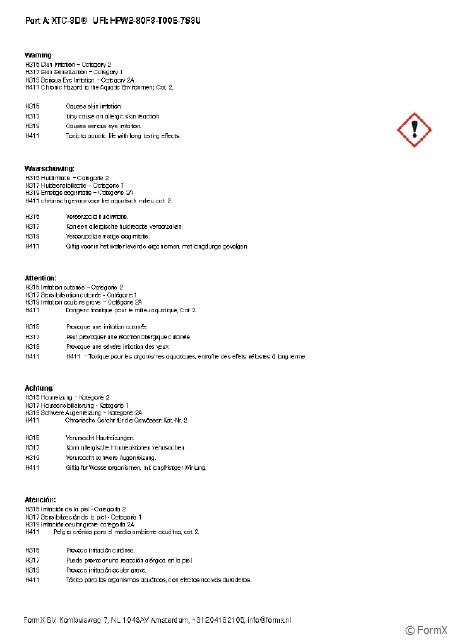

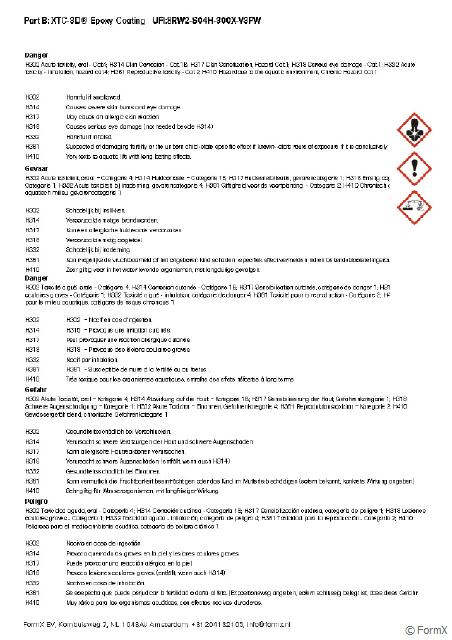

XTC3D Safety data

Protective coating for smoothing and finishing 3D printed parts that does not melt plastic. XTC‑3D® fills in 3D print striations and creates a smooth, high gloss finish. The need to post finish is almost eliminated. XTC‑3D® can be applied to both SLA and SLS prints. It works with PLA, ABS, Laywoo, Powder Printed Parts and other rigid media such as EPS, EPDM and urethane foam as well as wood, plaster, fabric, cardboard and paper.

XTC-3D® does not melt plastic. Two liquids are mixed together and brushed onto any 3D print, fabric, wood, and more. Coating self-levels and wets out uniformly without leaving brush strokes.

Features

Inexpensive to Use – 1 oz covers 100+ square inches (see coverage information below).

90% Time & Labor Savings: XTC-3D® fills in 3D print striations and creates a smooth, high gloss finish. The need to post finish is almost eliminated.

Coat any 3D Print Surface - XTC-3D® can be applied to both SLA and SLS prints. It works with PLA, ABS, Laywoo, Powder Printed Parts and other rigid media. It also can be used to coat EPS, EPDM and urethane foam as well as wood, plaster, fabric, cardboard and paper.

XTC-3D® does not contain VOC’s, phthalates or phosphates.

Preparation – Materials should be stored and used in a room temperature environment (23°C). Elevated temperatures will reduce Pot Life. XTC-3D® Part A resin and Part B Hardener must be properly measured and thoroughly mixed to achieve full, high-strength, solid-cure properties.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Avoid eye and skin contact. Avoid breathing fumes - use in a well ventilated area. NIOSH approved respirator is recommended. Wear safety glasses, long sleeves and rubber gloves to minimize skin contact. This material has a high exotherm (generates heat). Do not mix components in glass or foam containers.

Coverage – A very small amount of XTC-3D® is needed to coat an average size 3D print. 28.3 grams of mixed material will cover (651 cm2 ) applied at (.04 cm) thickness.

Pre-Mix Part B: Before using, shake container vigorously.

Measuring and Dispensing – You need to be accurate in measuring for XTC-3D® to cure properly. Parts A and B can be measured by either volume or weight. Dispense proper proportions of parts A and B into clean plastic, metal or wax-free paper containers (do not use foam or glass cups).

Extending Working Time - If left in a mixing cup with a concentrated mass, pot life will be short and material may cure in your cup due to exotherm. Important - Reduce the mass of the mixture to increase working time. Example: layer two sheets of aluminum foil together and create a single-use flat tray with vertical sides to contain the liquid resin. After mixing parts A and B, pour mixture into the aluminum foil to reduce the mass. Your working time will be significantly increased.

Mixing – Be sure mixing utensils have a square edge and are clean. Combine and mix proper amounts of Parts A and B. Mix thoroughly for at least 1 minute. Aggressively scrape the sides and bottom of mixing container several times. Use the square edge of mixing stick to bring material off of the sides and bottom of container and blend.

Important - Mixed XTC-3D® Resin is exothermic, meaning it generates heat. A large, concentrated mass of mixed material in a container can generate enough heat to melt a plastic cup, burn your skin or ignite combustible materials. If material begins to exotherm, move it to an open air environment.

Adding Color - XTC-3D® can be colored with SO Strong® color tints, UVO® color pigments or ignite color pigments. Pre-mix color with Part A before combining with Part B.

Adding Fillers - A variety of dry fillers can be added such as Cast Magic® or bronze or other metal powders, Glow Worm®, Quarry Tone® or Ure-Fil® powders. The maximum filler load is an amount equal to Part A by volume. Pre-mix filler with Part A before combining with Part B.

Applying XTC-3D® - Use a disposable chip brush or foam brush to apply XTC-3D®. To achieve the thinnest coating possible we recommend applying material with a foam brush. Brushing on one thin layer of mixed material is recommended for most prints to create a smooth, uniform coating: less than 1/64“(.039 cm). To avoid drips and runs, continue brushing and working the surface until the resin begins to set up. For particularly complicated prints with intricate detail you may want to coat one a section at a time for better control. XTC-3D® bonds to itself. If

Adding More Layers - allow first layer to partially cure until “tacky hard” before applying the next layer. For best results, each layer should be applied thinly: less than .039 cm.

Curing: One layer will cure tack free in about 2 hours at room temperature 23°C Mild heat 60° C will cure material within 15 minutes. Be careful: some 3D print media will melt at temperatures above 200°F. Fully cured material will be hard and unable to penetrate with a finger nail.

Post Finishing – Cured material can be machined or sanded (wear NIOSH approved respirator mask to prevent inhalation).

Painting – XTC-3D® can be painted and/or primed and then painted with acrylic enamel paints. For best results, lightly sand surface prior to painting.

Thinning XTC-3D® for Coating Starch / Powder Printed Parts: Viscosity can be lowered with acetone or denatured alcohol to penetrate porous parts.

The more solvent added, the longer XTC-3D® will take to cure. Cured material will be more flexible.

Smoothing Surface – granular surface texture can be smoothed by applying a second coat of XTC-3D® (for glossy finish) or lightly sanding for matte finish.

Warning – Do Not Spray XTC-3D® Read SDS for further information.

Applying a Release Agent – For applications where adhesion is not desired, a spray release Ease Release® 200 available from Smooth-On may be used.

Removing Uncured Material: Scrape as much material as possible from the surface using a scraper. Clean the residue with E-POX-EE KLEENER® available from Smooth-On, lacquer thinner, acetone or alcohol. Follow safety warnings pertaining to solvents and provide adequate ventilation.