- Home page

- 3D Printers and accessoires

- Modeling

- Molding & Casting

- Tin Silicones

- Platinum Silicones

- Dragon Skin™ Series

- Ecoflex™ Series

- Equinox™ Series

- Mold Star™ Series

- Rebound ™ Series

- Smooth-Sil™ Series

- SORTA-Clear™ Series

- Body Double™ Series

- Psycho Paint™

- Platsil Gel & Deadener

- Rubber Glass ™

- Encapso® K

- Solaris™

- Soma Foama™

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- PU-Rubbers

- Alginate

- PU-Resins

- PU Foam

- Epoxy Resins

- Polyester Resins

- Gypsum & Cement

- Latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica Latex Rubber

- Monstermakers Foam Latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Coating/Dipping Latex

- Holden's Body Latex™ - Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast

- Prince August

- Concrete Mixtures

- Jesmonite Acryl System

- Buddy Rhodes™ Concrete Products

- Seal and Release

- Additives

- Pigments

- Jesmonite liquid Pigments

- Pure Pigments powder

- Ultra Fine Pigments powder

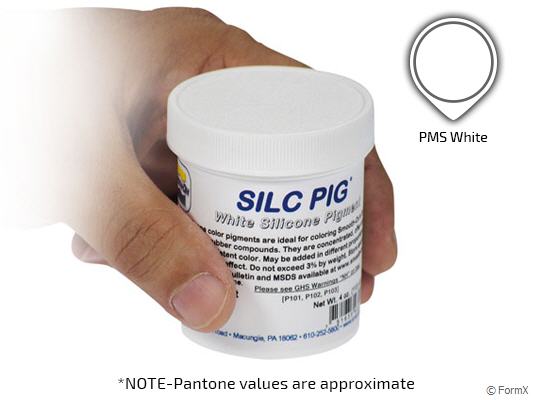

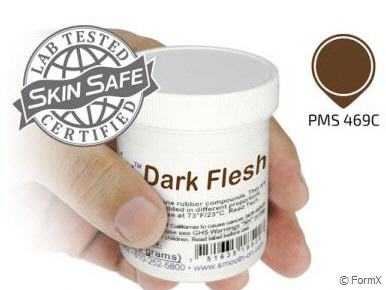

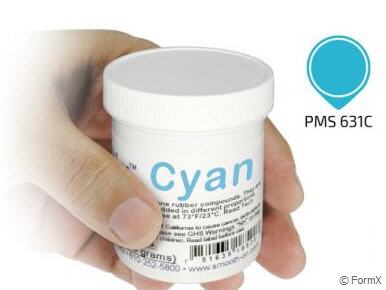

- Silc Pig™ pigments for silicone

- Glow Worm™ Fluorescent Pigments

- Cryptolyte™ Glow in the Dark

- Silicone Pigments - SilcPig™ Electric fluorescent

- Siltone Pigment for Silicone

- SilTone Kits

- Silicone Coloring System - FuseFX

- Silicone Coloring System S.A.M

- Key Pigments for silicone

- Kryolan Flock Fiber

- Latex Pigments

- Polyester Pigment

- UVO™- PU-pigments - UV-Resistant

- SO-Strong - PU-pigments

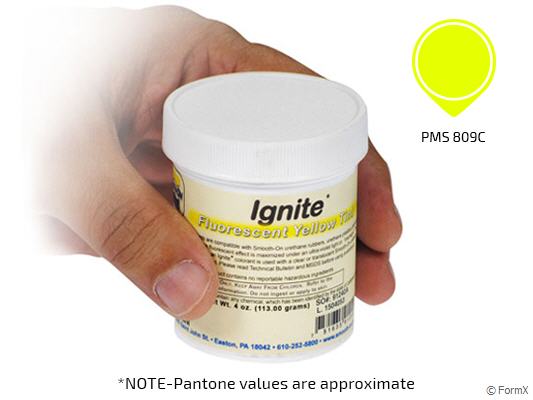

- Ignite™ fluorescent PU-pigments

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Powders

- Paints

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Vallejo Acrylic Paints

- Vallejo Metal Color

- Maker Pro Paint Additive

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- MM Latex Paint

- MM Latex Paint Base

- FFX LY-series paints

- FFX F-series paint

- FFX M-series paints

- jesmonite paint

- Fillers and Finishing

- Solvents & Thinners

- Adhesives

- Tools

- Equipment

- Special Make-Up

- Cannom Grease Paint

- Skin Illustrator Palettes

- Skin Illustrator Liquid

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60 ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras Liquids 60ml

- Mardi Gras Liquids 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Concentrates

- Fleshtone liquid Concentrate 60ml

- Dark Fleshtone liquid Concentrate 60ml

- FX liquid Concentrate 60ml

- FX liquid Concentrate 120ml

- Alchemy liquid Concentrate 60ml

- Grunge liquid Concentrate 60ml

- Mardi Gras liquid Concentrate 60 ml

- Necromania liquid Concentrate 60ml

- Necromania liquid Concentrate 120ml

- Concentrate Alphabetical

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Palettes

- PAX Paints Thomas Suprenant

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Old Age Stipple

- Holden's Cosmetic Latex™

- Tattoo Sheets

- Brushes Make-Up

- Stamps & Molds

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special effects

- Prostetic Materials

- Help me choose

- Literature

- FormX Academy

Rubberglass - Encapso K - Solaris

Rubberglass - Encapso K - Solaris

Encapsulating Silicones: Rubber Glass® II was developed specifically for special effects and display applications. -- Encapso® K is a water clear encapsulation rubber that looks just like water and is ideal for a variety of encapsulation and display applications -- Solaris is used for encapsulating photo cells.

Technical bulletin Rubber Glass

Technical bulletin Encapso K

Technical bulletin Solaris

Rubberglass

Rubberglass II

Rubber Glass® II is an improved tin-catalyzed silicone rubber product developed specifically for special effects and display applications. Two liquids (3 Parts A + 1 Part B) are mixed together and poured into a container. The mixture cures overnight to a solid water clear rubber that can then be easily broken or “crumbled” into pieces that look exactly like broken glass, ice or diamonds. Vibrant colors are possible by adding SilcPig® liquid color pigments. Rubber Glass® II is can be used to create a variety of special effects (i.e. simulated broken glass where human contact is required) and model effects (i.e. artificial ice or water). It can also be used for electronic encapsulation applications.

Encapso K

Encapso K

Encapso K® Water Clear Encapsulation / Display Rubber

Encapso® K is a water clear encapsulation rubber that looks just like water and is ideal for a variety of encapsulation and display applications.

How Does Encapso® K Work? - Two clear liquids (Part A and Part B) are mixed together in equal amounts. The mixture is then poured around artificial flower stems or over an object. Mixture turns from liquid to a solid, soft rubber over night. When cured, Encapso® K simulates water and will last a long time.

Encapso® K Advantages;

• Non-Hazardous & Non-Toxic - No dangerous chemicals

• Soft, Clear Rubber Lasts A Long Time

• Easy To Use - Mix two liquids in equal amounts and pour

• UV Resistant

• Cures without generating any dangerous heat or fumes

• Minimal Bubble Entrapment

• Cures perfectly clear - Looks just like water

• Cured rubber can be removed from object

Applications for Encapso® K

This rubber is perfect for encapsulating artificial flower stems to create artifical water for floral displays. You can also pour Encapso® K around just about any inanimate object to encapsulate for display. You can also create a variety of display props and novelty items. Encapso® K can be used to create water/pond effects for small scale model environments. Fully cured Encapso® K can also be crumbled to look like broken glass, diamonds or ice. Add color to Encapso® K with Silc Pig® or Ignite® liquid color pigments.

Solaris

Solaris Encapsulation Silicone

As solar panel technology advances, protecting electronic components that make turning the rays of the sun into usable energy becomes more of a challenge. Solaris® is an optically clear platinum silicone that lets light pass thorough it unimpeded. It is used to encapsulate expensive photovoltaic cells and protects them from shock, moisture, wind and other elements.

Solaris® is mixed 1A:1B by volume (no weighing scale necessary). It features a low viscosity and de-airs itself well. To aid in de-airing, the pot life is an extra-long 240 minutes. The rubber cures optically clear in 24 hours at room temperature. Solar panels can be put in service after 24 hours.

Maximizing Adhesion With Solaris® Bonding Primer – Solaris® silicone will adhere to clean solar panel glass substrates under most conditions. The slightest surface contamination or imperfections may result in the silicone separating from the glass. If that happens, the result is a costly solar panel failure. Solaris® Bonding Primer is the only way to ensure that the silicone will bond to the glass substrate.