- Home page

- 3D Printers and accessoires

- Modeling

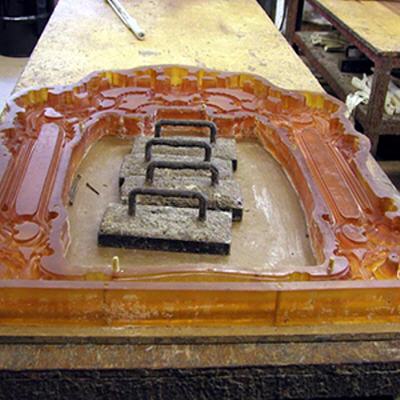

- Molding & Casting

- Tin Silicones

- Platinum Silicones

- Dragon Skin™ Series

- Ecoflex™ Series

- Equinox™ Series

- Mold Star™ Series

- Rebound ™ Series

- Smooth-Sil™ Series

- SORTA-Clear™ Series

- Body Double™ Series

- Psycho Paint™

- Platsil Gel & Deadener

- Rubber Glass ™

- Encapso® K

- Solaris™

- Soma Foama™

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- PU-Rubbers

- Alginate

- PU-Resins

- PU Foam

- Epoxy Resins

- Polyester Resins

- Gypsum & Cement

- Latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica Latex Rubber

- Monstermakers Foam Latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Coating/Dipping Latex

- Holden's Body Latex™ - Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast

- Prince August

- Concrete Mixtures

- Jesmonite Acryl System

- Buddy Rhodes™ Concrete Products

- Seal and Release

- Additives

- Pigments

- Jesmonite liquid Pigments

- Pure Pigments powder

- Ultra Fine Pigments powder

- Silc Pig™ pigments for silicone

- Glow Worm™ Fluorescent Pigments

- Cryptolyte™ Glow in the Dark

- Silicone Pigments - SilcPig™ Electric fluorescent

- Siltone Pigment for Silicone

- SilTone Kits

- Silicone Coloring System - FuseFX

- Silicone Coloring System S.A.M

- Key Pigments for silicone

- Kryolan Flock Fiber

- Latex Pigments

- Polyester Pigment

- UVO™- PU-pigments - UV-Resistant

- SO-Strong - PU-pigments

- Ignite™ fluorescent PU-pigments

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Powders

- Paints

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Vallejo Acrylic Paints

- Vallejo Metal Color

- Maker Pro Paint Additive

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- MM Latex Paint

- MM Latex Paint Base

- FFX LY-series paints

- FFX F-series paint

- FFX M-series paints

- jesmonite paint

- Fillers and Finishing

- Solvents & Thinners

- Adhesives

- Tools

- Equipment

- Special Make-Up

- Cannom Grease Paint

- Skin Illustrator Palettes

- Skin Illustrator Liquid

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60 ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras Liquids 60ml

- Mardi Gras Liquids 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Concentrates

- Fleshtone liquid Concentrate 60ml

- Dark Fleshtone liquid Concentrate 60ml

- FX liquid Concentrate 60ml

- FX liquid Concentrate 120ml

- Alchemy liquid Concentrate 60ml

- Grunge liquid Concentrate 60ml

- Mardi Gras liquid Concentrate 60 ml

- Necromania liquid Concentrate 60ml

- Necromania liquid Concentrate 120ml

- Concentrate Alphabetical

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Palettes

- PAX Paints Thomas Suprenant

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Old Age Stipple

- Holden's Cosmetic Latex™

- Tattoo Sheets

- Brushes Make-Up

- Stamps & Molds

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special effects

- Prostetic Materials

- Help me choose

- Literature

- FormX Academy

PU-Rubbers

PU-Rubbers

The workhorses in mold making. These rubbers give you bang for your buck. Solid performing, shrink free mold rubbers that will last forever casting concrete, gypsums, resins etc.

PU Rubbers

PU Rubbers

PU Additives

PU-Additives

Table Overview

PMC Properties Table

| PMC | A:B mixing ratio | Demold Time | Elongation at Break | Mixed Viscosity | Pot Life | Shore A Hardness | Tear Strength | Specific Gravity kg/lt |

| 744 | 2:1 weight/ volume | 16 hrs | 400 % | 3400 cps | 15 min | 44 A | 90 pli | 1,000 |

| 746 | 2:1 weight/ volume | 16 hrs | 650 % | 1200 cps | 15 min | 60 A | 100 pli | 1,000 |

| 770 | 2:1 by weight | 16 hrs | 600% | 3000 cps | 35 min | 70 A | 160 pli | 1,015 |

| 780 | 2:1 weight/ volume | 48 hrs | 700% | 2000 cps | 25 min | 80 A | 200 pli | 1,015 |

| 790 | 2:1 weight/ volume | 48 hrs | 600 % | 3000 cps | 20 min | 90 A | 300 pli | 1,068 |

Vytaflex Table

| VYTAFLEX® | Mixture (by Volume) | Mixed Viscosity (mPas) | Specific Weight (g/cm⊃3;) | Pot Life (min) | Cure Time (hrs) | Colour | Hardness (Shore A) | Tensile Strength (N/mm) | Elongation at Break (%) | Schrinkage (%) |

| 10 | 1A:1B | 3100 | 1,00 | 30 | 24 | creme | 10 | 200 psi | 1000 | <0,1 |

| 20 | 1A:1B | 1000 | 1,00 | 30 | 16 | amberclear | 20 | 200 psi | 1000 | <0,1 |

| 30 | 1A:1B | 1800 | 1,02 | 30 | 16 | creme | 30 | 500 psi | 1000 | <0,1 |

| 40 | 1A:1B | 2000 | 1,03 | 30 | 16 | creme | 40 | 522 psi | 660 | <0,1 |

| 45 | 1A:1B | 2000 | 1,04 | 30 | 16 | creme | 45 | 886 psi | 900 | <0,1 |

| 50 | 1A:1B | 2000 | 1,04 | 60 | 16 | creme | 50 | 588 psi | 400 | <0,1 |

| 60 | 1A:1B | 2000 | 1,04 | 60 | 16 | creme | 60 | 880 psi | 480 | <0,1 |

Clear Flex Series

| Clear-Flex™ | Mixture | Mixed Viscosity (mPas) | Specific Weight (g/cm3) | Pot Life (min) | Cure Time (hrs) | Colour | Hardness (Shore A) | Tensile Strength (N/mm) | Elongation at Break (%) | Schrinkage (%) |

| 30 | 1A:1B(Weight) | 750 | 1,03 | 15 | 16 | clear | 30 | 5 | 675 | ,2 |

| 50 | 1A:2B(Volume) | 250 | 1,04 | 25 | 16 | clear | 50 | 4,3 | 500 | 0,15 |

| 95 | 1A:1,5B(Volume) | 250 | 1,04 | 25 | 16 | clear | 95 | 35,7 | 175 | 0,28 |

Econ 80, Simpact & Urecoat

| Mixture (by Volume) | Mixed Viscosity (mPas) | Specific Weight(g/cm³) | Pot Life (min) | Cure Time (hrs) | Colour | Hardness (Shore A) | Tensile Strength (N/mm) | Elongation at Break (%) | Schrinkage (%) | |

| Econ 80 | 1A:1B(volume&weight) | 1,200 | 1,06 | 13 | 24 | translucent | 80 | 5,6 | 125 | ,014 |

| Simpact 85 A | 85A:100B(weight) | 1,100 | 1,09 | 4 | 48 | off-white | 85 | 6,6 | 165 | <,07 |

| Urecoat | 100A:10B(weight) | 3,800 | 8 | 16 | translucent amber | 70 | 9,4 | 875 | - |

Guide

Let us help you find your way.

The list below may help you find what you are looking for via an alternative path.