- Home page

- 3D Printers and accessoires

- Modeling

- Molding & Casting

- Tin Silicones

- Platinum Silicones

- Dragon Skin™ Series

- Ecoflex™ Series

- Equinox™ Series

- Mold Star™ Series

- Rebound ™ Series

- Smooth-Sil™ Series

- SORTA-Clear™ Series

- Body Double™ Series

- Psycho Paint™

- Platsil Gel & Deadener

- Rubber Glass ™

- Encapso® K

- Solaris™

- Soma Foama™

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- PU-Rubbers

- Alginate

- PU-Resins

- PU Foam

- Epoxy Resins

- Polyester Resins

- Gypsum & Cement

- Latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica Latex Rubber

- Monstermakers Foam Latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Coating/Dipping Latex

- Holden's Body Latex™ - Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast

- Prince August

- Concrete Mixtures

- Jesmonite Acryl System

- Buddy Rhodes™ Concrete Products

- Seal and Release

- Additives

- Pigments

- Jesmonite liquid Pigments

- Pure Pigments powder

- Ultra Fine Pigments powder

- Silc Pig™ pigments for silicone

- Glow Worm™ Fluorescent Pigments

- Cryptolyte™ Glow in the Dark

- Silicone Pigments - SilcPig™ Electric fluorescent

- Siltone Pigment for Silicone

- SilTone Kits

- Silicone Coloring System - FuseFX

- Silicone Coloring System S.A.M

- Key Pigments for silicone

- Kryolan Flock Fiber

- Latex Pigments

- Polyester Pigment

- UVO™- PU-pigments - UV-Resistant

- SO-Strong - PU-pigments

- Ignite™ fluorescent PU-pigments

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Powders

- Paints

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Vallejo Acrylic Paints

- Vallejo Metal Color

- Maker Pro Paint Additive

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- MM Latex Paint

- MM Latex Paint Base

- FFX LY-series paints

- FFX F-series paint

- FFX M-series paints

- jesmonite paint

- Fillers and Finishing

- Solvents & Thinners

- Adhesives

- Tools

- Equipment

- Special Make-Up

- Cannom Grease Paint

- Skin Illustrator Palettes

- Skin Illustrator Liquid

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60 ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras Liquids 60ml

- Mardi Gras Liquids 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Concentrates

- Fleshtone liquid Concentrate 60ml

- Dark Fleshtone liquid Concentrate 60ml

- FX liquid Concentrate 60ml

- FX liquid Concentrate 120ml

- Alchemy liquid Concentrate 60ml

- Grunge liquid Concentrate 60ml

- Mardi Gras liquid Concentrate 60 ml

- Necromania liquid Concentrate 60ml

- Necromania liquid Concentrate 120ml

- Concentrate Alphabetical

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Palettes

- PAX Paints Thomas Suprenant

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Old Age Stipple

- Holden's Cosmetic Latex™

- Tattoo Sheets

- Brushes Make-Up

- Stamps & Molds

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special effects

- Prostetic Materials

- Help me choose

- Literature

- FormX Academy

Sil-Poxy™ Adhesive

Buy Smooth-On at FormX

Smooth-On is one of the worlds leading manufaturers 3D modeling materials such as mold-making, casting and special effects materials but also industrial casting resins, adhesives and equipment. FormX is main distributor of Smooth-On products in Europe.

Sil-Poxy™ Silicone Adhesive

Sil-Poxy™ is a one component adhesive made specifically for bonding Smooth-On RTV moldmaking silicone rubbers to silicone rubber and other substrates including some plastics (urethane), plasters/ceramics, fabrics, etc. Sil-Poxy™ will work with Smooth-On tin or platinum cure moldmaking silicones and provides a strong, flexible bond between silicone parts with high elongation. Can be colored with Silc-Pig™ silicone pigments. Cured adhesive resists weathering, moisture, UV and high temperatures. Sil-Poxy™ can be used repairing torn silicone rubber molds. Other applications include bonding silicone for prosthetics and animatronics.

Cured Sil-Poxy™ is certified skin safe. IMPORTANT - Do not apply to skin in liquid form.

Features

- Can be used repairing torn silicone rubber molds.

- Will work with tin- or platinum-cure silicones

- Provides a strong, flexible bond

Technical bulletin Sil-Poxy adhesive

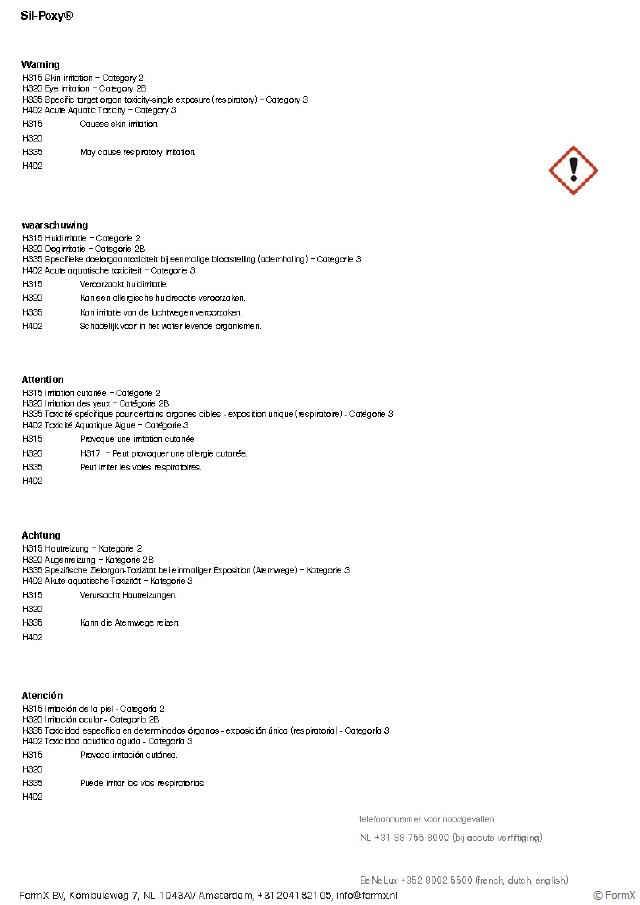

- Read the safety information label. Click on the image

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild

- Lisez les informations de sécurité cliquez sur l'image

Silicone Adhesives

Safety - Use in a properly ventilated area (“room size” ventilation). Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.

Store and use material at room temperature 23°C. This product has a limited shelf life and should be used as soon as possible.

A clean, dry surface is essential for successful adhesive bonding. If possible, abrade surface and follow with solvent wipe before applying.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Dispensing - Squeeze tube, taking care not allow air to enter tube before replacing cap. Unused product in tube exposed to air will cure quickly.

Applying - Apply adhesive to surface and mate parts. Material will begin to cure in 15 minutes. Pieces can be handled after 1 hour. Full cure is attained after 24 hours. Warmer temperatures (and higher humidity) will result in a faster cure. Lower temperature will retard cure.

Guide

Let us help you find your way.

The list below may help you find what you are looking for via an alternative path.